Biorefinery: 7 Ways It’s Turning Trash into Treasure Worldwide

Introduction

A biorefinery is more than just a waste management solution—it’s a cornerstone of the circular economy. By converting everyday trash into valuable fuels, chemicals, and materials, biorefineries are helping communities tackle waste, reduce carbon emissions, and create new economic opportunities.

In this guide, we’ll explore how biorefinery technologies—such as plastic pyrolysis, food waste composting, and thermal waste treatment—are reshaping the future of sustainable energy. Whether in developed nations or rapidly growing developing economies, these innovations are proving that waste can become a powerful resource.

The potential is huge: from reducing landfill pressures to generating renewable energy, biorefineries are bridging the gap between waste and value. Below, we’ll look at the main types of biorefineries, the feedstocks they rely on, and the key benefits and challenges that come with adopting these systems.

Transforming Waste into Resources: Is it Possible?

Budget limitations and inadequate infrastructure often hinder sustainable waste management in the developing world. As a result, a large portion of generated organic waste is in unhygienic dumpsites or landfills, leading to severe environmental, economic, and social ramifications. However, this issue offers economic and ecological opportunities, such as the strategic deployment of biofuels from non-food feedstocks, which could significantly reduce land use impacts and greenhouse gas emissions.

The Role of Waste Biorefineries in a Circular Economy

Waste biorefinery is the answer to transforming waste into valuable resources. Using technologies such as pyrolysis, fermentation, and gasification, these facilities convert non-food feedstocks into fuel, enabling a circular economy. Waste biorefineries can handle various feedstocks and produce various products, addressing waste disposal woes, meeting the growing energy demands, and creating new businesses and job markets.

Waste biorefineries, especially in developing countries, are an untapped resource. They can transform current waste disposal practices and generate substantial economic value. However, technical and regional issues must be tackled to implement this, along with a thorough analysis of economic and environmental impacts.

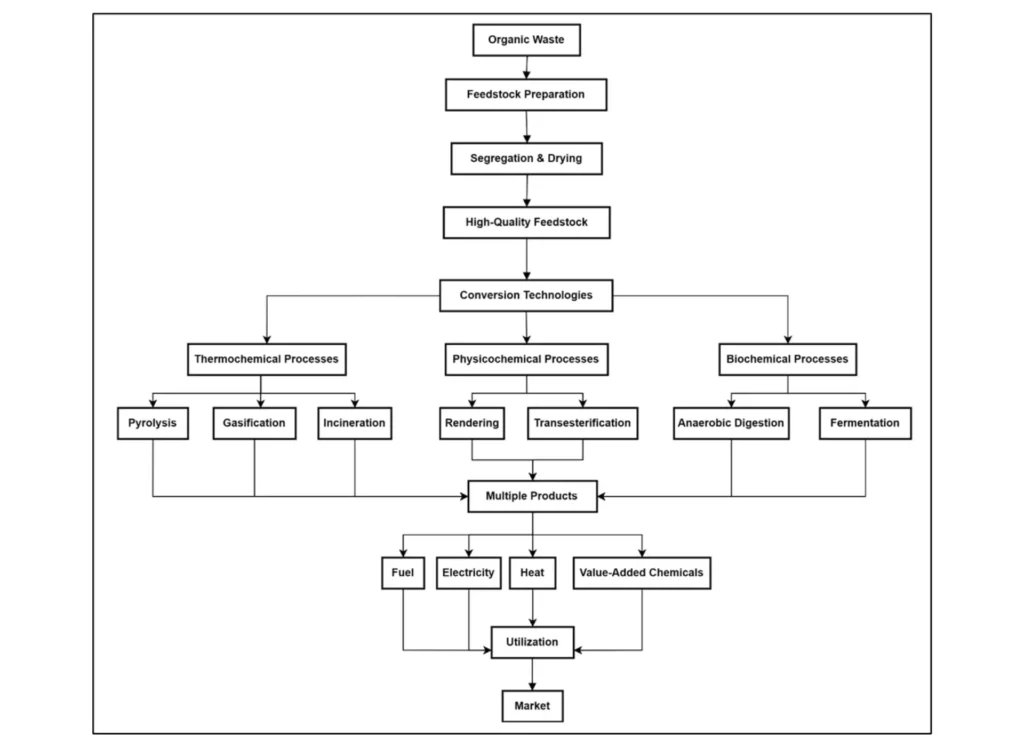

Exploring the Different Energy Conversion Routes in Waste Management

Waste-to-energy (WTE) or biorefinery technologies can solve the pressing issues of increasing energy demands and the need for sustainable waste management in developing countries. They follow three primary pathways: thermochemical, physicochemical, and biochemical processes. These technologies convert feedstocks into fuels, electricity, heat, and value-added products through different mechanisms. The success of these technologies is vital to creating sustainable circular economies in developing countries.

How Do We Choose the Right Waste Biorefinery Technology?

Many scientists have researched biorefinery technologies to identify optimal solutions for specific regions, focusing on incineration as a preferred method for energy generation in developing countries like Bangladesh. However, challenges such as high moisture content in municipal solid waste (MSW), which could lower its heating value in incineration facilities unless the waste is segregated at the source or pre-dried, must be addressed. In addition, there is an ongoing debate about the suitability of anaerobic digestion (AD) over incineration, and vice versa, for energy production.

Incineration is a common electricity and heat production technology in several advanced countries. It offers advantages such as lower capital and operational costs, reduced complexity, and lesser labor skill requirements, making it feasible for any urban city. Nevertheless, it has drawbacks in producing higher greenhouse gas emissions and harmful gases, leading to air and water pollution. Therefore, developing an incineration facility requires efficient emission-cleaning technology and acceptance by the local public.

What Are the Pros and Cons of Different Biorefinery Technologies?

Other technologies, like refuse-derived fuel (RDF), carry a higher complexity and skilled labor requirements than incineration and AD technologies but cause less environmental pollution. In addition, RDF has comparable capital and net operational costs to incineration based on the cost per ton of waste per year.

AD technology offers the lowest net capital and operational costs based on cost per ton of waste per year compared with incineration and RDF technologies. It provides an economical solution for waste disposal problems in developing countries, with lower technology complexity and skilled labor requirements. It has been estimated that, on average, 120-150 m3 of biogas with a total energy value of 2500 MJ/t can be produced from one ton of dry MSW using AD technology.

What Factors Should Influence Our Choice of Biorefinery Technology?

The choice of these technologies for any developing country will depend on various factors, including waste, capital and operational costs, technological efficiencies, complexities, availability of skilled labor, and geographical location of the facilities. Before developing any biorefinery technology in a developing country, the following criteria are recommended:

- Waste Composition and its biochemical characterization

- Waste generation rates for each type of waste

- Energy contents of each type of waste

- Advantages and limitations of each biorefinery technology for a particular region

- Technical and economic benefits of each biorefinery technology for a particular region

- Life cycle assessment (LCA) of biorefinery technology, including its technical, economic, and environmental assessment.

What is a Biorefinery, and How Has the Concept Evolved?

A biorefinery is a multifaceted system that can process various or mixed feedstocks simultaneously and in place, yielding multiple products. This concept evolved from petroleum refineries, and several small-scale biorefineries have been developed worldwide.

Biorefineries generate fuels, heat, power, materials, chemicals, feed, and organic fertilizer from different fractions of municipal solid waste (MSW). For example, in green biorefineries, grass or grass silage is used to produce fiber cake and nutrient juice, the former transformed into bioproducts such as dyes, pigments, and crude drugs, while the latter is converted into feed pellets used as raw material for chemical production.

How Are Biorefineries Classified in the Scientific Literature?

There is no standard classification of existing and emerging biorefineries. Their classification depends on feedstock sources, although the desired form of energy or bioproducts and the availability and quantity of feedstock also shape the technology route for a biorefinery. Biorefineries can also be categorized based on the products, feedstock types, and technologies.

Based on conversion technologies, biorefineries are broadly classified into primary (conventional) and secondary (advanced). Primary biorefineries process unprocessed feedstocks like fuelwood, wood chips, and solid pellets, while secondary biorefineries process feedstock into products like ethanol, biodiesel, biogas, and dimethyl ether.

How Are Biorefineries Categorized Based on Raw Materials or Feedstocks?

Depending on the raw materials or feedstocks, biorefineries are classified into the first, second, third, and fourth generations. The feedstocks needed to produce liquid fuels in these biorefineries mainly come from forestry, agriculture, municipal, or industrial wastes. Examples of biorefineries based on the feedstocks include whole crop, oleochemical, lignocellulosic, marine, and green biorefineries. Biorefineries produce fuels in solid forms such as fuelwood, charcoal, and timber pellets, liquid forms like biodiesel, ethanol, and pyrolysis liquid oils, or gaseous forms such as methane and hydrogen.

What are Different Types of Waste Biorefinery?

Waste biorefineries vary mainly based on the origin and nature of the feedstock. For example, agricultural waste biorefineries use agricultural residues, while forestry waste biorefineries use forest-originated biomass. Municipal or industrial waste biorefineries depend on processes, leftovers, and domestic waste, while aquaculture biorefineries use algae and seaweed biomass. In addition, an electro-biorefinery concept has been proposed for gaseous feedstock, such as carbon dioxide (CO2).

How to Do Agriculture-Based Biorefineries Work?

Agriculture-based biorefineries harness various agricultural residues and biomass as crop waste, tea and tobacco seed, tomato seed, citrus, and green waste. For example, one study examined the generation of bioethanol from cellulose and biohydrogen from hemicelluloses of wheat straw, along with biogas from the waste of bioethanol and biohydrogen processes, aiming to evaluate an effective, low-cost technology under the biorefinery concept. They concluded that an integrated waste biorefinery approach, which produces multiple biofuels from waste, was more sustainable and energy-efficient than a single-fuel generation.

What Does Forestry-Based Biorefinery Entail?

Forests cover a significant part of the earth’s surface and contribute considerably to the total standing biomass. The biomass they produce can provide a constant feedstock supply to waste biorefineries. Energy generation from forestry waste biomass has acquired attention, especially with the rise of forestry biorefineries that use pulp and paper mill residues to produce multiple fuels and value-added chemicals, increasing revenue without disturbing the forest flora.

How Does Industrial Waste Biorefinery Function?

Industrial waste biorefineries consume substantial natural resources, like those in the paper and pulp industry. These industries produce sludge rich in carbohydrate content, making it a promising source of cellulose-derived fuels and value-added materials in an industrial waste biorefinery. Using paper sludge in biorefineries offers advantages like minimal or no pretreatment of the cellulose material because of the intensive pulping process.

How Is Food Waste Managed in a Biorefinery?

Food waste biorefineries handle waste from catering services, expired food products, and professional environments like offices. Developing a food waste biorefinery requires geographic location determination, addressing logistics related to waste collection and transportation, quantifying food processing amounts, and assessing the most sustainable processing route to maximize end-products, minimize costs, reduce greenhouse gas emissions, and use non-renewable energy efficiently.

What is the Role of Animal Waste in Biorefineries?

Animal waste, including waste cooking oil, can be highly valuable in a waste biorefinery. In addition, animal slaughtering waste can generate a significant amount of biodiesel, meat and bone meal (MBM), and glycerol. This resulted in a large potential for electricity generation, with cumulative net savings based on landfill diversion, carbon credits, fuel savings, and electricity generation estimated in the millions.

How Does a Wastewater Biorefinery Function?

Almost 90% of generated wastewater worldwide is directly discharged into water bodies untreated, posing severe environmental and health risks. Hydrogen production from wastewater within a waste biorefinery can treat wastewater and generate renewable energy. However, despite the existence of several techniques for hydrogen production, many are not feasible on a large scale due to high costs and excessive CO2 emissions.

What is Potential of Plastic Waste Refineries?

Plastic waste, one of the largest waste streams, can be transformed into liquid fuel and other valuable products using pyrolysis technology. Although, in several developing nations, plastic waste comprises up to 20% of the city’s waste, it was found that pyrolysis could effectively convert large amounts of plastic waste into liquid fuel and char, with a high potential for electricity generation. Additionally, a plastic waste refinery projected significant carbon savings and economic benefits.

What are Algae-Based Biorefineries?

Algae-based biorefineries utilize microalgae, a source of polysaccharides, polyamines, carotenoid pigments, and polyunsaturated fatty acids, to produce multiple fuels and animal feed. However, despite the high potential for biofuel production because of their lipid content, algae biorefineries often struggle with the scarcity of freshwater required for microalgae growth. As a solution, using naturally occurring microalgae in seawater is being explored, particularly in coastal areas of developing countries.

Challenges and Perspectives of Waste Biorefineries in Developing Countries

Developing waste biorefineries in developing countries presents a promising solution to address energy security issues and high costs associated with conventional fuels. However, the high capital intensity of these biorefineries and the complexities related to the variability in chemical characteristics of derived products from different feedstocks present significant challenges. Incorporating multiple conversion technologies could mitigate these issues by reducing overall costs.

Like their petroleum-based counterparts, biorefineries are characterized by their capital and energy-intensive nature. A significant amount of heat and electricity is needed for processes such as pretreatment and purification. Biochemical technologies, in particular, have been criticized for their lengthy and multifaceted biological techniques, causing larger equipment and increasing capital. Integrating biorefinery processes into existing industries is proposed as a potential solution to balance these capital costs.

The review also emphasizes the environmental advantages of waste biorefineries, such as the potential utilization of biogas in cooling systems or for energy generation. Implementing Life Cycle Assessment (LCA) methodologies is deemed crucial in evaluating the sustainability of these biorefinery processes. In conclusion, despite the complex challenges surrounding developing and implementing waste biorefineries in developing countries, they hold great potential to enhance energy security and environmental sustainability.

How Can Developing Countries Implement the Biorefinery Concept Successfully?

Developing countries are rich in renewable resources such as waste recyclables, which can serve as crucial feedstock, ensuring their independence from fossil precursors and fresh raw materials. Moreover, by adopting innovative and optimized waste management approaches, these nations can produce marketable products, transforming traditional, linear industries into waste-based factories.

How Can a Closed-Loop Approach Aid in Developing Waste Biorefineries?

A shift from the existing informal approach to energy recovery and recycling towards a closed-loop system would aid economies in transitioning towards waste biorefineries. Furthermore, fully using these bio-resources could lead to innovative technological models and better markets for bio-based products, aligning with the goals of sustainable development and a zero-waste Earth.

What Role Do Interdisciplinary Collaborations Play in Enhancing Environmental and Economic Systems?

Interdisciplinary regulatory policies and collaborations between biotechnology, engineering, chemistry, and environmental sciences are crucial to improve existing LCA tools, leading to a more sustainable environmental and economic system. For example, a sustainable biorefinery should aim to produce fuels and other bio-products with greener footprints using LCA studies, serving as a high-quality alternative for feedstock utilization.

Why Should Greenhouse Gas Effects Be Considered in Waste Biorefinery Evaluations?

The evaluation of a waste biorefinery should not overlook the impact of greenhouse gases (GHGs), as they play a significant role in the biorefinery’s operation and economic value. Integrated biorefineries need to consider the cycles of biological systems and processes that drive waste management systems.

How Can Waste Biorefineries Contribute to Sustainable Production?

Waste biorefineries generate green energy, utilize zero-waste production technologies, and encourage the production of environment-friendly products with low carbon and water footprints. They should be capable of generating a wide range of marketable products and power sustainably, ultimately achieving the goals of circular economies. The sustainability of waste biorefineries also hinges on factors such as not competing with biomass and food-based feedstocks, water use, product quality, land use, and impacts on biodiversity.

Conclusion

Waste biorefineries can revolutionize sustainable waste management in developing countries, yielding considerable economic and environmental benefits. These include energy recovery, value-added product creation, land conservation, new business opportunities, reduced GHG emissions, and natural resource savings. However, choosing the suitable waste biorefinery type requires comprehensive social, financial, technical, and environmental assessments via LCA.

To Cite this article:

‘A.S. Nizami. Turning Trash into Treasure: How Biorefineries Can Revolutionize Developing Economies. 2023. Publication & Data. Green Flagship.’